Superfinishing stones for bearings, shafts, rollers

Superfinishing or "super finishing" is the process applied at the final end when making as fine and smooth surfaces as possible for metal parts, such as raceway surface of bearings and shafts. The main reason why super finishing stones are applied in the final polishing process is to reduce the friction caused to the metal, which leads to its constant wearing out. Wear often leads to the degradation of the metal parts. Data shows that bearings with or without superfinishing appear to have completely different life spans. This is critical because in most part, these kinds of auto-parts desired stability. For mechanical parts, which require less friction, this super finishing process is indispensable to maintain their functions.

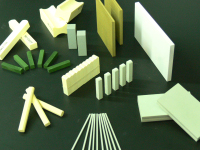

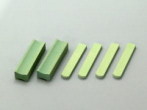

A super finishing stone comprises a piece of small block usually tailor-made for the user's application, and each size varies depending on the work materials.

The leading end of this stone can be fabricated into a concave round or round shape depending on the work materials. This is similar to the honing process but distinct because of its particularity. Conventionally, a superfinishing stone is also considered a honing stone.

WA(Aluminum Oxide based) has sharp edge

GC(Silicon Carbide based) contains hard abrasives to give fine surface

EP(WA with special modification) is for roller, through feed processing

CBN(Cubic Boron Nitride) has unique characteristic on life. Affective for miniature bearing processing etc.

Mechanism of superfinishing process

The super finishing stone will polish the surface of the material that you are going to process through an oscillating and rotating motion. The contact face will be by aspect rather than point contact. During the process, once a superfinishing stone has been attached to the holder, the stone will be used until it outlives its usefulness. Thus, the process has to continue without any dressing of the superfinishing stone. This process is quite different from diamond tools, such as metal or resin bonds.

Conventionally, WA (white fused alumina), GC (green carbide), and Chromium are the grains applied to the superfinishing stone, but these days, CBN (cubic boron nitride) has been applied to this process as well. The main purpose for applying CBN is to reduce the time lost during exchanging the superfinishing stone. Compared to the conventional types of grains, such as WA or GC, CBN has a longer life along with higher cutting power. However, because of its cost, majority of the superfinishing stones are WA or GC grain types.

The surface roughness of these applications are sometimes measured by their "sound." During each production process, the surface roughness will be measured, but for the final check, conventional measurement equipment cannot determine the quality. The surface of the work materials will be in a cross-hatched pattern, unlike a mirror finishing, because of the material's rotation during the superfinishing process. However, sounds differ according to these slight cross-hatched patterns made on the surface.

Propose the best honing stone for each applications

There are three types of superfinishings: through-feed, plunge, and wheels. The dependency on the superfinishing stone is quite high when manufacturing a product with a super fine finish; so, in order to fulfill our customer's requirements, wide variations of this product are available.

To achieve high cutting edge with longer life we have applied customized vitrified bonds with porous structure for this stone. Several grains are available such as WA, GC, WG (a mixture of WA and GC), and CBN. Depending on the final quality and issue to be solved, we can propose what is the best type of superfinishing stone for you.