Products for floor polishing

Floor polishers

Many professional have been using our floor polisher for stone restoration and granite and marble floor polishing. We have designed this especially for floor use, and it is suitable for granite, marble, as well as terrazzo-engineering stone. A polishing pad can be attached by Velcro, which takes no time for exchanging the tools.

By pushing the red button on the right hand grip, you can adjust the water that flows out from the water tank. This will ease the process of cleaning your work place during and after the floor polishing. In addition, since the water flow affects the polishing results, you can adjust this amount to each work place condition.

Water flow through a tube is connected to the center of where the polishing pad attached. A soft rubber tire is applied to avoid scratches on the stone floor. Above the polishing head, there is a space to put weight in order to control the pressure. You can trust this light but powerful floor polisher to ease your floor work and finish it fast.

See more details about floor polisher| Application | Stone floor polishing, wide area such as floor |

|---|---|

| Work material | Stone (Granite, Marble, Limestone, Sandstone), Terrazzo (Artificial stones) |

| Electrical voltage | 100-120V or 200-240V |

| Power consumption | 1.3KW |

| Rotating speed | 200 (50 Hz) to 240 (60 Hz) min-1 |

| Weight | 35 kg |

| Power current | 13 to 14A |

| Cord length | 12 m |

| Motor | 1 1/4 HP or 1 1/2 HP |

Marble floor polishing pad | SR series M type

Floor polishing pad specially designed for marble polishing can be used on engineering stones. Attach them to the floor polisher (three pieces recommended) and supply enough water to get the best results. Use with caution and as per the specified directions (please refer to the pictures below). The ideal working time in each step for these pads is 2 min/m2. One set of discs can polish up to 150 m2 of flooring.

| Application | Floor, stone interior and exterior |

|---|---|

| Work material | Marble, Travertine, Limestone |

| Diameter | 90 mm |

| Grit size | 300, 500, 1000, 2000, 3000, 8000 |

| Life time | 150 to 400 square meters(depend on working condition) |

| Recommended polishing time per square meter | 2 minutes (using 3 pads) |

Granite floor polishing pad | SR series G type

Specially designed diamond discs for granite floor polishing and maintenance are also suitable for polishing ceramic tiles. Outer diamond chips are tapered to ease polishing over lippages. Grooves are cut radially so that pads can be attached in any direction. Granite is much harder than marble, and thus, it is highly effective in placing additional weights on the polishing machine for more aggressive cutting on granite.

Attach them to the floor polisher (three pieces recommended) and supply enough water to get the best results. The ideal working time in each step for these pads is 3 min/m2. One set of discs can polish up to 150 m2 of flooring.

| Application | Floor, stone interior and exterior |

|---|---|

| Work material | Granite, Sandstone (Hard type stones) |

| Diameter | 90 mm |

| Grit size | 300, 500, 1000, 2000, 3000, 4000, Buff(for light color stone), Buff (for dark color stone) |

| Life time | 150 to 400 square meters(depend on working condition) |

| Recommended polishing time per square meter | 3 minutes (using 3 pads) |

Granite buffing disc | Marble buffing disc | Black type

This granite buffing pad is especially designed for dark color granite, marble, tile and stone such as black, green and red. In order to achieve finest mirror like finish, there's another option such as using higher grit, but talking about granite floor, buffing pads can be the only one to achieve the "highest" gloss. Floor will be much more glossy than just waxing.

Attach them to floor polishing machines (three or six pieces recommended) and suply little amount of water. Be careful not to supply too much water since buffing process need polishing resistance.

| Application | Floor, stone interior and exterior |

|---|---|

| Work material | Granite, Marble, Terrazzo, Engineering stones, Tile |

| Diameter | 90 mm |

| Color | Black |

| Recommended polishing time per square meter | 3 minutes (using 3 pads to 6 pads) |

Granite buffing disc | Marble buffing disc | White type

This granite and marble buffing pad is suit to light color natural stone floor such as white, yellow and light brown. Like above mentioned, the purpose of buffing is to shine the floor like mirror. To achieve this, use less water compare to previous process by diamond polishing pads. Buff need certain amount of polish resistance to work effectively. This will be the final process for floor polishing so take heed not to catch up small sand particles or other unwanted foreign objects. We guarantee the amazing high gloss achieved by this buffing pads.

Attach them to floor polishing machines (three or six peices recommended) and suply little amount of water. Be careful not to supply too much water since buffing process need polishing resistance.

| Application | Floor, stone interior and exterior |

|---|---|

| Work material | Granite, Marble, Terrazzo, Engineering stones, Tile |

| Diameter | 90 mm |

| Color | White |

| Recommended polishing time per square meter | 3 minutes (using 3 pads to 6 pads) |

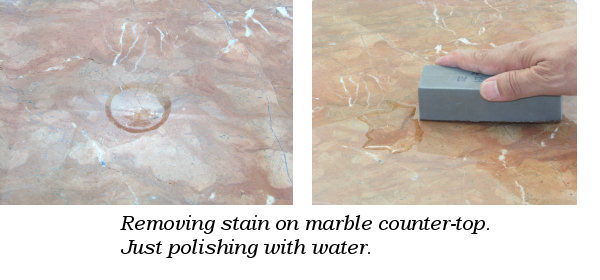

Marble polishing sponge for hand use

If you want to remove stains on a small area such as part of the marble table or kitchen, this palm size marble polishing tools will be of your help. Spilled carbonated drink or fruit juice easily stains the marble stone. If you polish or use chemical all over the place, it will be too extreme for just a small stain.

You do not need any machine or equipment except water and this sponge. For an abrasive part with a groove, a small-sized diamond is included. The grit size variation is as follows.

| Application | Small area or corner |

|---|---|

| Work material | Marble stone |

| Grit size | 500, 1000, 2000, Finishing |